Revolutionary 3D Printing Technology at FAMU Could Transform Space Exploration

By Tisha Keller, FAMU-FSU School of Engineering

Joint college researchers develop advanced materials enabling astronauts to manufacture essential components during missions

Breakthrough research in advanced 3D printing technology at Florida A&M University could fundamentally transform how astronauts sustain themselves during long-duration space missions, eliminating dependence on Earth-supplied materials and enabling on-demand manufacturing in space.

The pioneering work, led by Professor Subramanian Ramakrishnan from the Department of Chemical and Biomedical Engineering at the FAMU-FSU College of Engineering, has secured $5 million in NASA funding to develop next-generation materials critical for future space exploration.

“Imagine while on a space mission having the ability to print sensors, radiation shields, or even functional tissues as the mission progresses,” says Ramakrishnan. “This capability could change the space exploration paradigm, making missions more sustainable and adaptable to unforeseen challenges.”

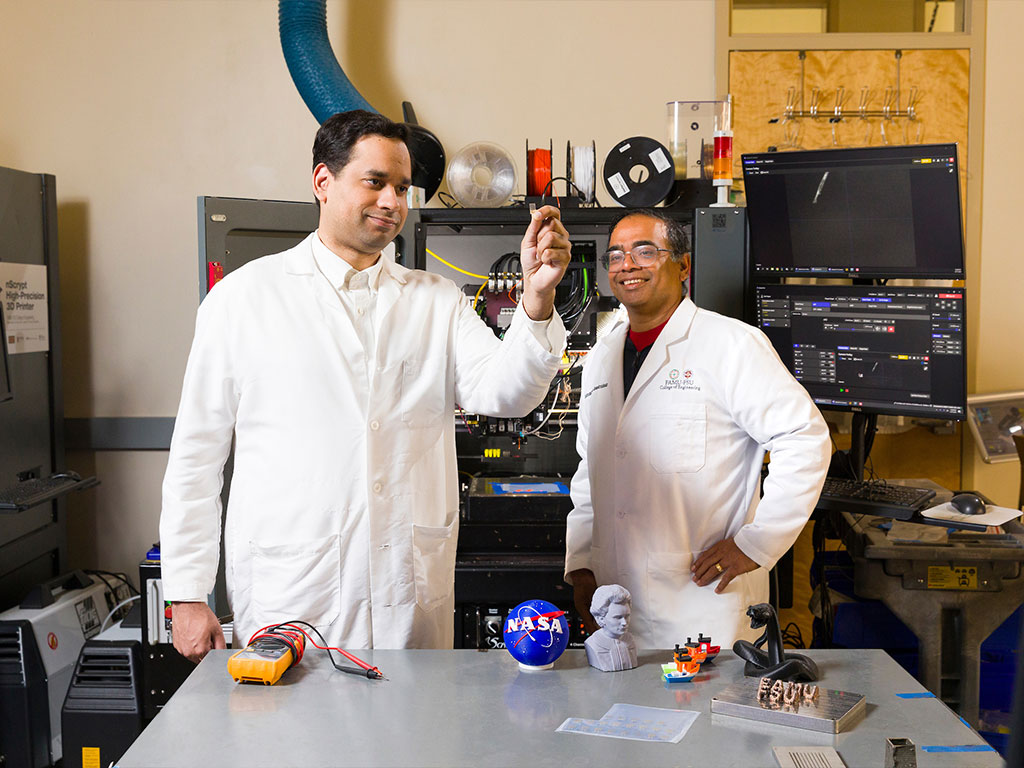

Left to Right: Assistant Professor Jamel Ali and Professor Subramanian Ramakrishnan

Left to Right: Assistant Professor Jamel Ali and Professor Subramanian Ramakrishnan

(Photo by Scott Holstein)

Creating Next-Generation Materials for Space Manufacturing

Ramakrishnan’s team is developing specialized 2D materials called MXenes, along with metallic and semiconducting nanoparticles, to create advanced inks specifically designed for 3D printing in extraterrestrial environments.

“These advanced inks are used to print everything from sensors that detect gases and strain, to antennas, radiation shielding and flexible electronic circuits,” Ramakrishnan said. “They are especially important for 3D printed materials used on space missions.”

This research represents a crucial step toward in-space manufacturing (ISM), empowering astronauts to produce what they need while in orbit rather than relying on materials transported from Earth.

Harnessing Extraterrestrial Resources

Among the most promising innovations is the utilization of lunar and Martian soil—known as regolith—to create specialized printing materials for future Moon and Mars missions. This approach turns local resources into valuable construction materials, potentially enabling sustainable habitation on other worlds.

The interdisciplinary team collaborating on this research includes Satyanarayan Dev from FAMU’s Department of Biological Systems Engineering, Richard Liang from Florida State University, and Margaret Samuels from NASA’s Goddard Space Flight Center.

“This system has the critical capability for us to complete the manufacturing of precise sensor patterns in a single step to ensure high-quality device integration and on-demand design and manufacturing,” Ramakrishnan explained.

Precision Printing Technologies

The researchers have developed an innovative technique called Electrohydrodynamic (EHD) printing, which uses electric fields to precisely deposit nanoparticles for flexible electronic sensor applications.

“By combining this printing technique with laser curing we can rapidly manufacture the sensors and speed up the manufacturing process,” Ramakrishnan said. “This streamlined approach is crucial for future space missions, especially when working on the International Space Station.”

To advance their capabilities, the university has acquired an advanced nScrypt 6-axis 3D printing system through an additional $700,000 National Science Foundation grant. This specialized equipment can create intricate designs on curved surfaces, particularly valuable for aerospace and medical device applications.

“We are experimenting with innovative ink formulations and techniques. The equipment is helping us produce new and exciting next-generation sensors for NASA,” Ramakrishnan added.

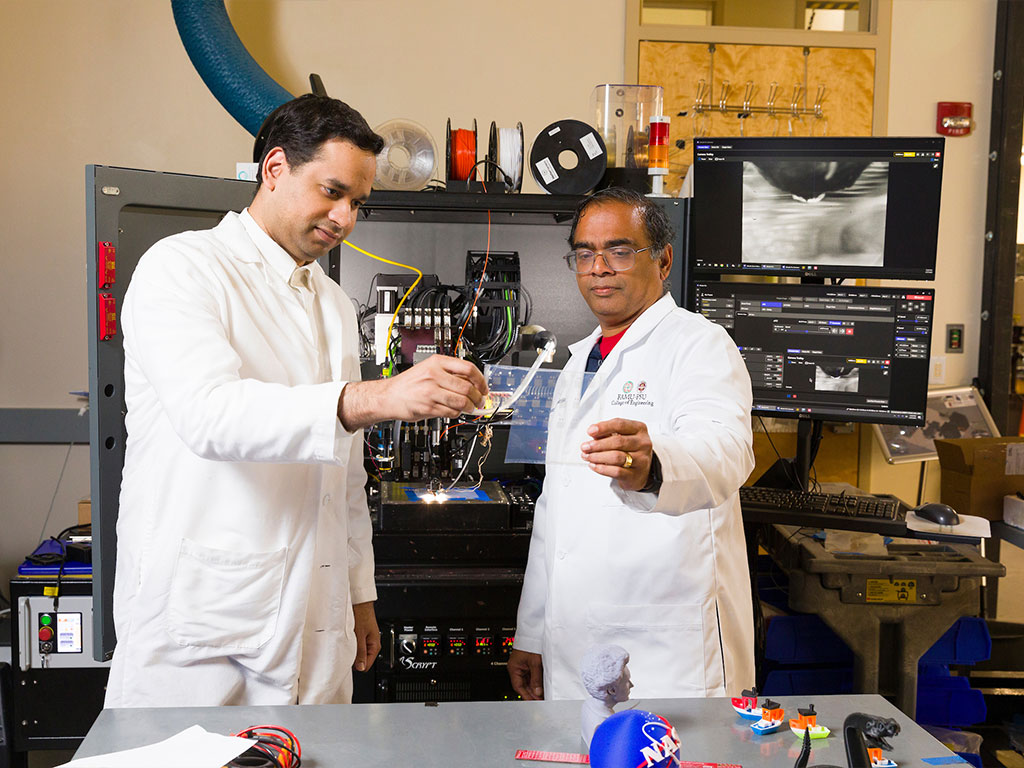

The FAMU-FSU School of Engineering professors are using their research for innovative

solutions.

The FAMU-FSU School of Engineering professors are using their research for innovative

solutions.

(Photo by Scott Holstein)

Biomedical Frontiers in Microgravity

Complementing the materials research, Co-Director and Assistant Professor Jamel Ali is investigating how human cells self-assemble in microgravity environments similar to those on the Moon and Mars.

Ali’s team studies the behavior of 3D-printed tissues in space with implications for therapeutic cell expansion and regenerative medicine. His collaborators include Emily Pritchard from the FSU Medical School and researchers at the Mayo Clinic in Jacksonville working in partnership with NASA’s Kennedy Space Center.

The research addresses the unique challenges of 3D printing biological materials on curved surfaces, with applications that extend far beyond space exploration into medical innovations that could benefit patients on Earth.

Transforming Multiple Scientific Fields

The technological breakthroughs emerging from this research program have implications reaching well beyond NASA missions. The novel sensors, tissues, and organs being developed could revolutionize biomedicine and materials science, providing solutions for pressing health challenges while advancing technology across numerous sectors.

Through this cutting-edge research, FAMU and the joint college are establishing themselves as a leader in space materials science while developing technologies that will enable sustainable, long-duration space exploration and potentially transform manufacturing both in space and on Earth.

Media Contact:

Rachel James-Terry

rachel.jamesterry@famu.edu

Latest FAMU News

- Big Bend Regional Small Business Week 2025 Highlights Innovation, Leadership, and Local Impact<![CDATA[Big Bend Regional Small Business Week 2025 Highlights Innovation, Leadership, and Local Impact]]>

- Florida Emancipation Day, FAMU Farm Fest Celebrate History, Agriculture, and Community Engagement<![CDATA[Florida Emancipation Day, FAMU Farm Fest Celebrate History, Agriculture, and Community Engagement]]>

- FAMU Interim President Beard Addresses the Upcoming Leadership Transition<![CDATA[FAMU Interim President Beard Addresses the Upcoming Leadership Transition]]>

- FAMU Clarifies: No Suspensions Related to Recent Petition or Prayer Vigil<![CDATA[FAMU Clarifies: No Suspensions Related to Recent Petition or Prayer Vigil]]>

- Florida A&M University Board of Trustees Selects Marva Johnson as the 13th President<![CDATA[Florida A&M University Board of Trustees Selects Marva Johnson as the 13th President]]>

- Florida A&M University Welcomes Rafael Vazquez to the Board of Trustees<![CDATA[Florida A&M University Welcomes Rafael Vazquez to the Board of Trustees]]>